With our commitment to customer satisfaction and quality, we strive to deliver the best heating solutions.

High temperature resistance up to 350°C

External insulation structure that minimizes heat loss

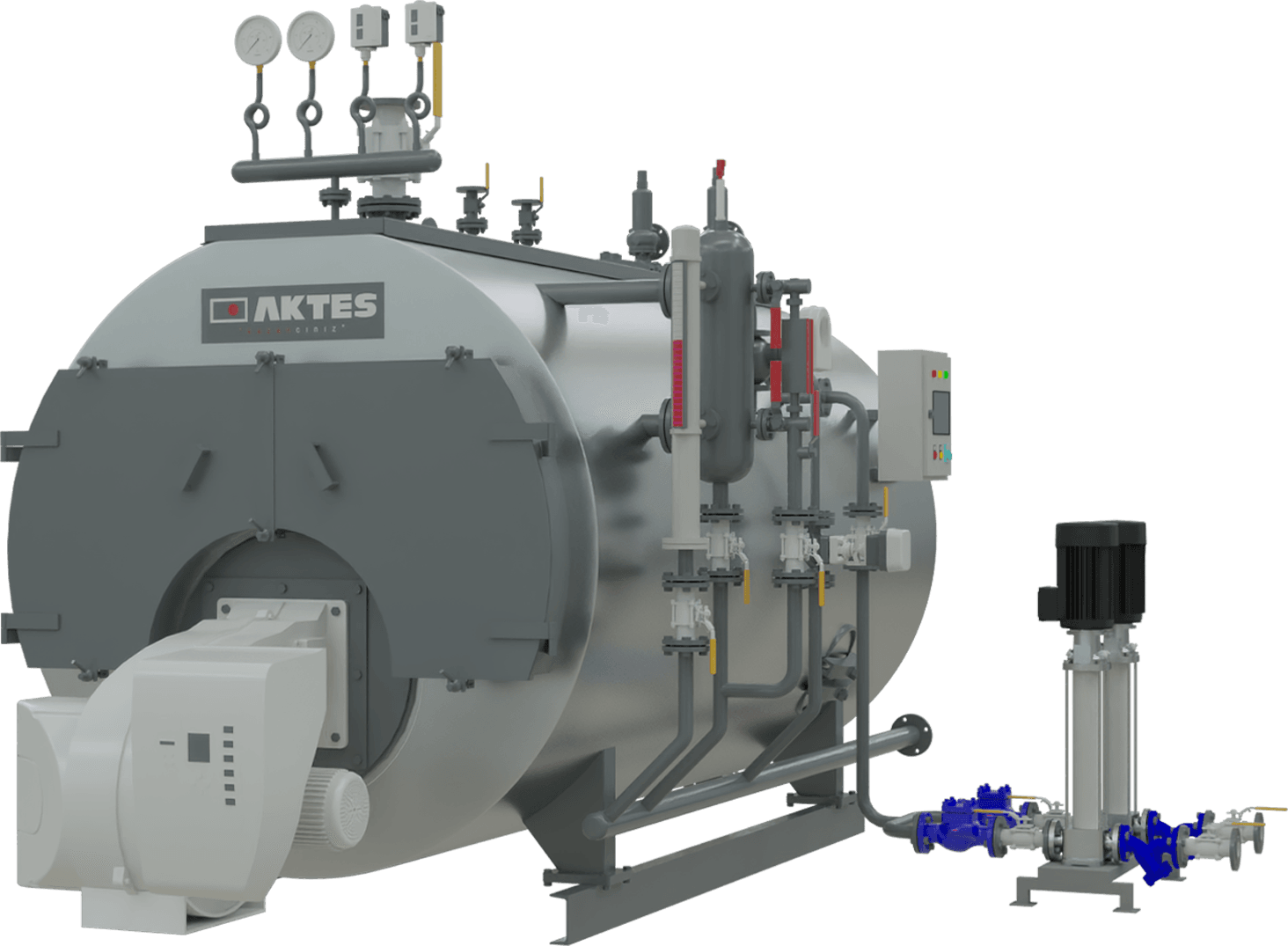

Three-pass design with spiral coil

Heating fluid circuit resistant to 18 bar pressure

Product Features

Product Advantages

Advantages of Aktes KYK Series

Provides efficient and uninterrupted operation in industrial production processes with high temperature capacity.

All weld joints of the tubes in the coil undergo 100% radiographic testing.

Our welded fabrications are carried out by certified welders in accordance with approved WPS and WPQR standards. MIG-MAG and SMAW welding methods are applied during production according to relevant norms.

Provides long-lasting operation and low maintenance costs thanks to durable engineering design.

Offers long-term use and low operating costs thanks to stainless materials.

Provides safe and efficient operation by protecting against overheating and pressure.

Şehrinizi seçin, size en yakın servisimizi bulalım.

Şehrinizi seçin, size en yakın servisimizi bulalım.