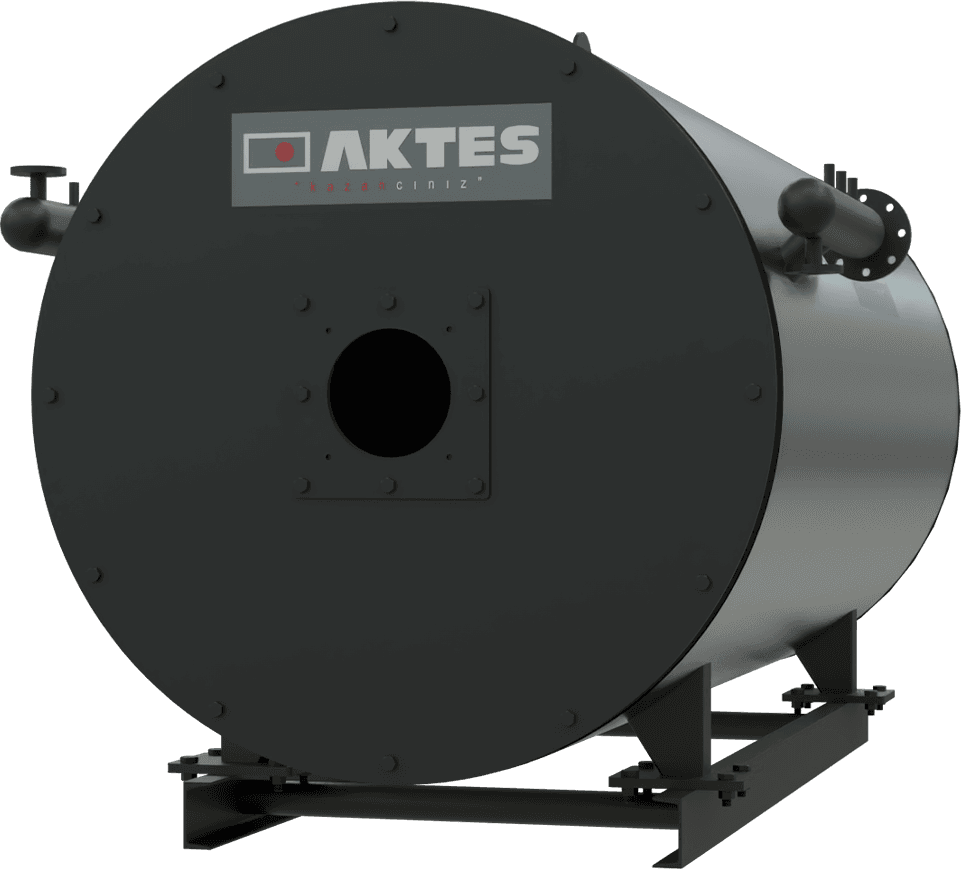

Environmentally Friendly Technology with SSB Series

Operating pressure ranging from 3 to 16 bar

High efficiency rate between 90% and 95%

Low combustion chamber load

Corrugated furnace resistant to pressure of 8 bar and above

Product Features

Product Advantages

With our commitment to customer satisfaction and quality, we strive to provide the best heating solutions

Provides safe steam production in industrial facilities with an operating pressure range of 6-16 bar.

Offers energy savings and low operating costs with an efficiency rate of up to 95% when used with an economizer.

Low combustion chamber load ensures complete combustion, energy savings, and long-lasting, high performance.

The corrugated furnace structure, resistant to pressures of 8 bar and above, provides long-lasting and safe operation.

Ensures the burner fan operates with minimal energy consumption, offering lower energy costs.

Provides flexible operation with various fuel options, including gas, liquid, biogas, and biofuel.

Frequently Asked Questions

We work to provide the best heating solutions with our commitment to customer satisfaction and quality.

- Provides higher efficiency.

- Reduces fuel consumption.

- Minimizes energy loss by lowering flue gas temperature

- Industrial facilities.

- Food production plants.

- Hotels.

- Hospitals.

- Textile factories.

- Central heating systems

- The combustion chamber should be cleaned regularly.

- Burners and control panels should be checked periodically.

- Water level and pressure should be monitored regularly.

- Safety valves and sensors should be inspected at least once a year by a professional team

- Overtemperature and overpressure protection systems.

- Automatic shutdown mechanism.

- Low water level protection.

- Safety valves and alarm systems

Şehrinizi seçin, size en yakın servisimizi bulalım.

Şehrinizi seçin, size en yakın servisimizi bulalım.