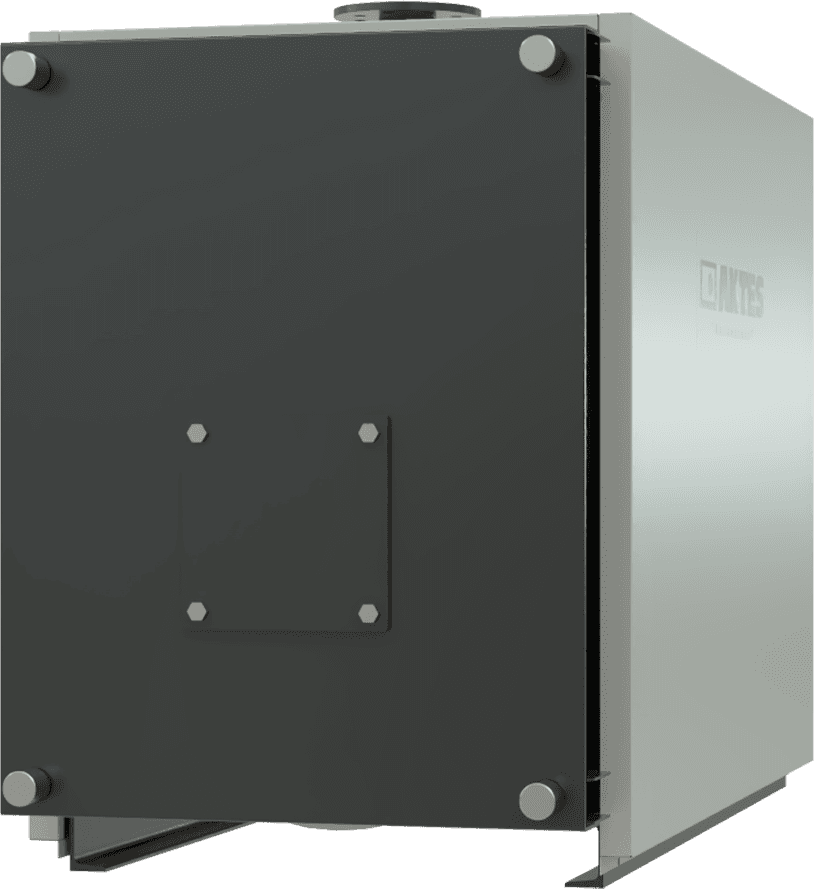

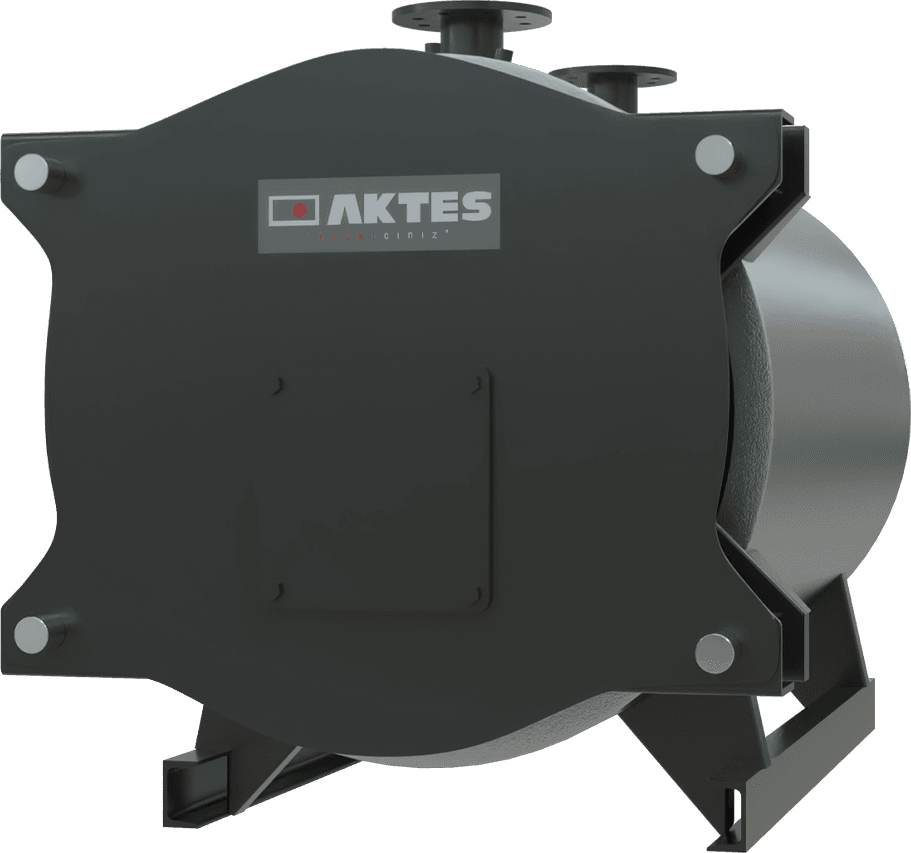

Practical and Durable AKS Series Products

Many people turn to the opportunities offered by technology to meet the hot water needs of industrial facilities. Some of the systems in Aktes Isı’s wide product range are suitable for meeting your hot water requirements. Our AKS series, which includes a variety of models, is a prime example of these products. By gaining detailed information about the AKS series, which can be used in industrial areas of different sizes or buildings, you can select the model that best suits your needs.

What Is the AKS Series?

The AKS series is our product group consisting of fully cylindrical, three-pass hot water boilers that operate on solid fuel. These boilers feature special grate surfaces designed to maximize efficiency from solid fuels. With up to 85% efficiency, the AKS series helps reduce energy costs, and its technical specifications vary by model. You can easily choose the appropriate unit for your facility by considering criteria such as nominal output power, flue gas temperature, and boiler water volume.

These products can also be equipped with an automatic combustion (stoker) feature upon request, allowing the system to operate continuously without manually reconnecting the boiler when the fuel runs out. The system automatically activates when the chamber fuel is depleted, ensuring uninterrupted heat transfer. The AKS series is very easy to use, requiring no professional assistance. Our hot water boilers, which ensure continuous industrial production, can be utilized in factories or workshops operating in various sectors.

Features of AKS Series Products

The AKS series features a fully cylindrical combustion chamber and offers models suitable for both narrow and wide spaces. By considering the width, length, and height of the hot water boilers in our category, you can select the model that best fits your needs, allowing you to use your workspace more efficiently. Large-capacity boilers can heat large volumes of water to the desired temperature in a single cycle.

With the fan option, our hot water boilers can achieve a 15–20% increase in capacity. The maximum energy output of the AKS series can reach up to 2,000,000 kcal/h. These products have a maximum operating temperature of 90°C and withstand a pressure of 3 bar. If you require boilers capable of operating under higher pressures, you can contact the Aktes Isı team.

Applications for the AKS Series

The AKS series can be used in many areas where hot water is needed, including:

-

Various Types of Buildings: AKS series boilers can be installed in residential buildings, stores, or workplaces, providing access to hot water at any time of the day.

-

Industrial Areas: If your production processes require hot water, the AKS series may be suitable. Hot water boilers are commonly used in sectors such as textile, food processing, chemical, and pharmaceutical industries.

-

Agriculture and Livestock Activities: The AKS series can be used for heating greenhouses, producing hot water on farms, or preventing water from freezing. These solid-fuel boilers operate independently of natural gas.

-

Sports and Recreation Facilities: Pools, SPA centers, saunas, and thermal facilities can benefit from the AKS series to serve a larger number of people. Compact boilers can be installed wherever needed.

AKS Series Products for Various Budgets

The price of solid fuel hot water boilers in the AKS series varies depending on the features and design of the product. Factors such as nominal output power, water volume, flow rate, and dimensions directly affect pricing. Designed and manufactured by Aktes Isı’s experienced team, the AKS series includes products built to last for years. You can place an order for a hot water boiler by considering the condition of your living or working spaces and your production capacity.

Şehrinizi seçin, size en yakın servisimizi bulalım.

Şehrinizi seçin, size en yakın servisimizi bulalım.